Products & Solutions

AONA designs and manufactures nanocrystalline ribbons, nanocrystalline cores, common-mode chokes, EMI filter assemblies and current sensors for EV power electronics, industry and renewable energy.

Nanocrystalline Ribbons

Nanocrystalline Common-mode inductive cores

Magnetic stamped sheet

EMI Filter Assemblies

Specific EMI Filter Assemblies

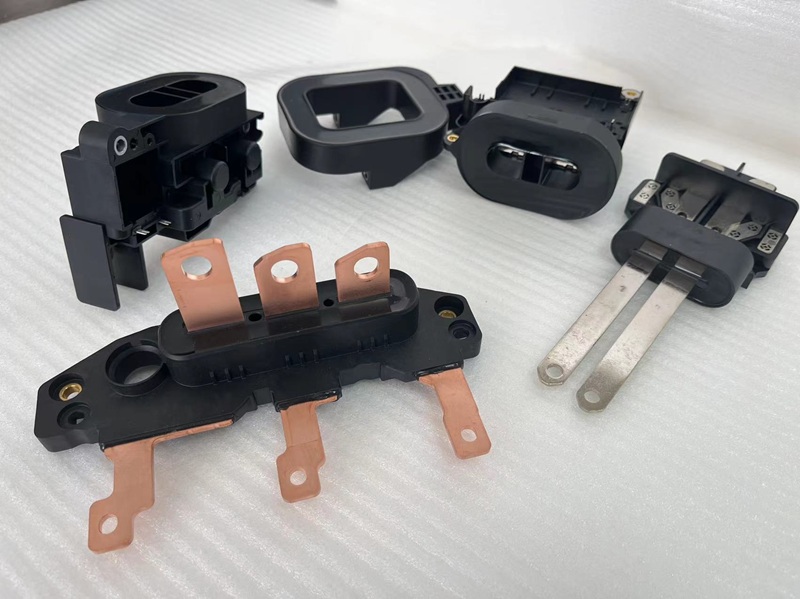

Common Mode Chokes

Based on our Nanocrystalline cores, we offer customer specific CMCs

Current sensors

Safety Devices and Energy Meter

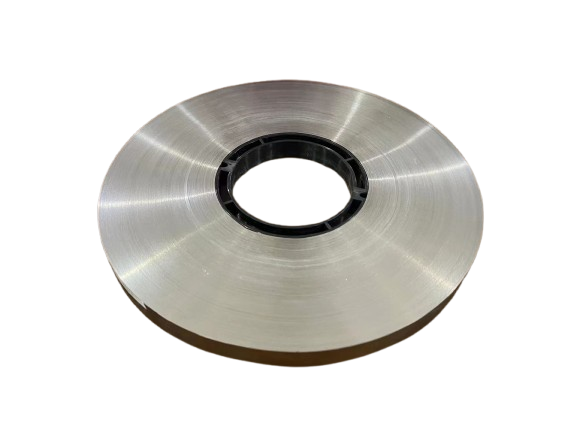

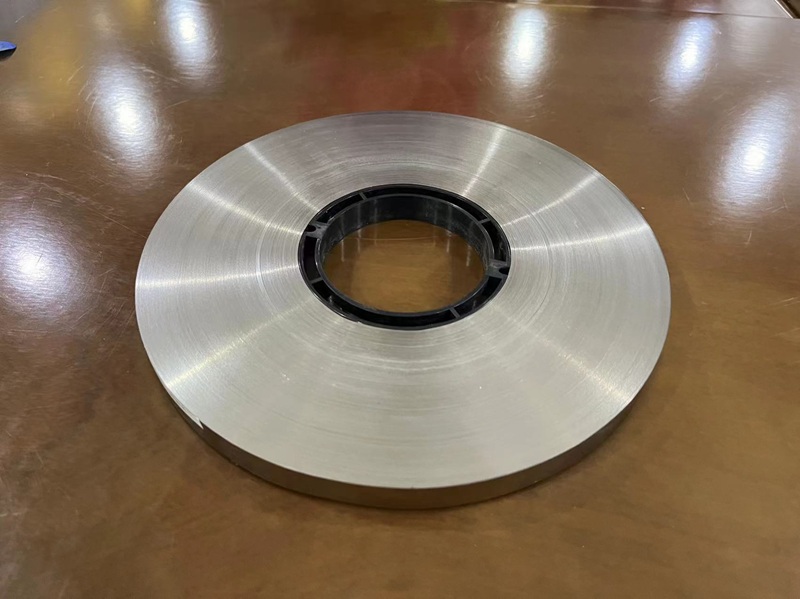

Nanocrystalline Ribbons

Iron-based nanocrystals alloys are composed primarily of Fe, Nb, Cu, Si, B.

When an iron-based amorphous alloy containing copper and niobium is annealed above its crystallization temperature, it forms an ultra-fine grain structure with grain sizes as small as 10–20 nanometers. This controlled crystallization process transforms the amorphous alloy into a nanocrystalline structure with outstanding magnetic and mechanical properties.

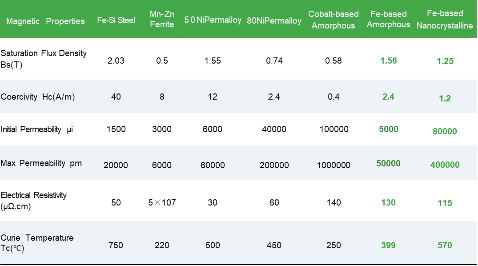

Performance Comparison Table

Nanocrystalline materials offer a unique combination of advantages:

High saturation magnetic flux density

Very high initial and maximum permeability

Low coercivity and core loss

Excellent thermal and magnetic stability

High mechanical strength, wear, and corrosion resistance

Thanks to their exceptional performance and cost-effectiveness, nanocrystalline alloys are rapidly replacing traditional materials like silicon steel, permalloy, and ferrites in various applications. They are ideal for use in medium- and high-frequency transformers, current transformers, and a wide range of inductive components.

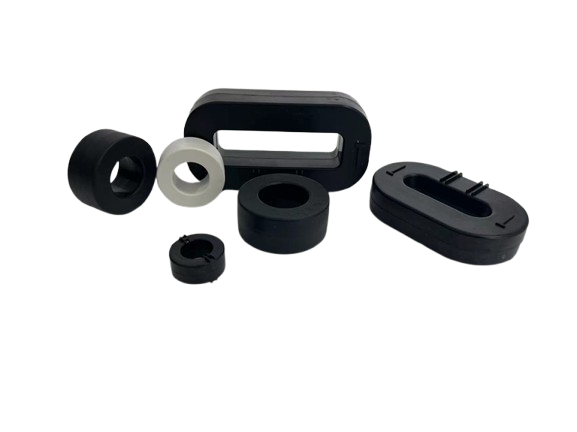

Nanocrystalline Common-mode inductive cores

Cased cores

Cased cores are assembled with a protective plastic housing to facilitate handling and integration. Two common fixation methods are used: potting and gluing, depending on the mechanical and thermal requirements. By selecting appropriate case materials, these cores can be tailored to withstand various operating temperatures. Magnetic permeability can be customized between 2,000 and 150,000 at 10 kHz, and up to 35,000 at 100 kHz.

Bare cores

Bare nanocrystalline cores are impregnated with a silicone resin solution to provide mechanical stability and a certain degree of hardness, without adding significant bulk. This treatment helps maintain the core’s structural integrity while allowing for compact assembly designs. The magnetic permeability can be tailored to application needs — ranging from 2,000 to 150,000 at 10 kHz, and up to 35,000 at 100 kHz.

Coated Cores

Coated cores are treated with an epoxy resin coating, offering a balance between bare and fully cased cores. The coating provides mechanical hardness, electrical insulation, and good heat resistance, making them suitable for compact assemblies with moderate protection needs. Magnetic permeability can be adjusted between 2,000 and 150,000 at 10 kHz, and up to 35,000 at 100 kHz.

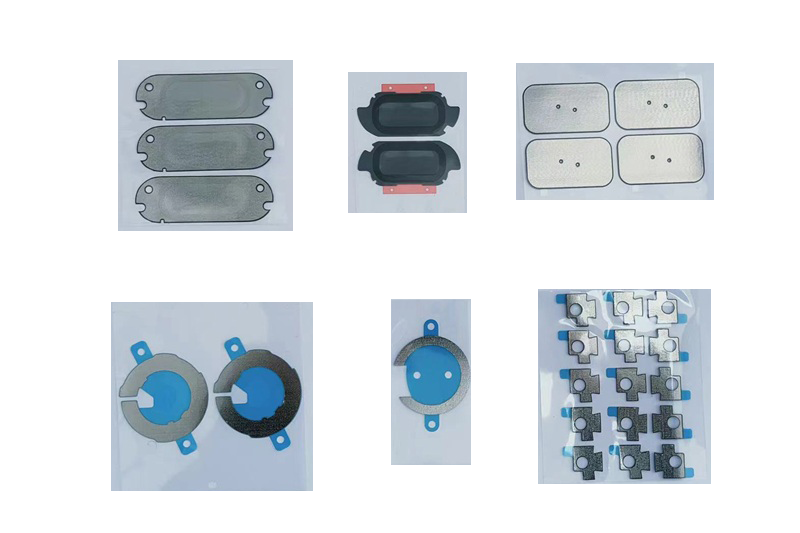

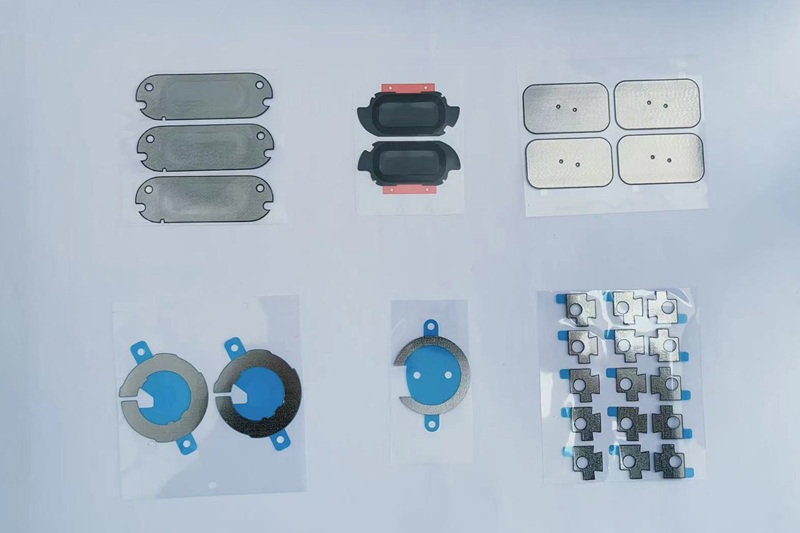

Magnetic stamped sheet

Laminated magnetic sheets are manufactured from nanocrystalline strips that are wound into large coils and then annealed to optimize magnetic performance. After annealing, the strips undergo a lamination process using a combination of 3 μm adhesive film and nanocrystalline layers, applied in two passes to enhance mechanical integrity and thermal durability.

Once laminated, the material is processed by cutting individual sheets from the master coil using precision die-cutting techniques.

Key material characteristics:

Saturation magnetic flux density: up to 1.25 T

Curie temperature: up to 570 °C

Crystallization temperature: approximately 500 °C

Permeability: ~1,000 at 1 MHz

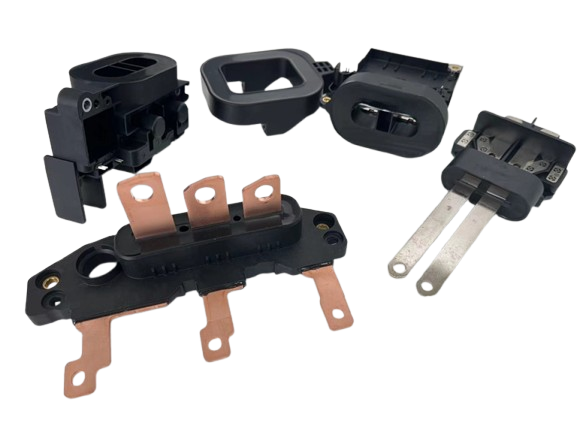

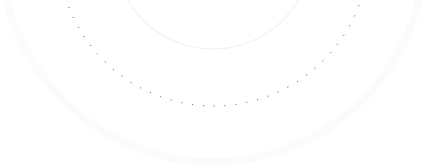

EMI Filter Assemblies

We offer customer specific EMI Filter Assemblies based on our Magnetic material, providing an EMC-optimized solution that can be directly integrated into the customer’s application.

Common Mode Chokes

Based on our Nanocrystalline cores, we offer customer specific CMCs

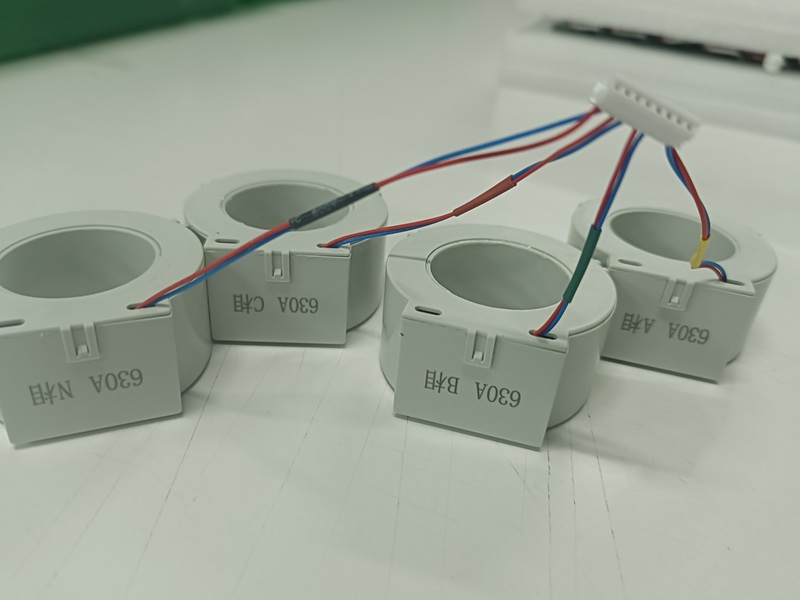

Current Sensors

Safety Devices (RCCB ,…)

Nanocrystalline cores are widely used in electromagnetic Residual Current Circuit Breakers (RCCBs). For AC-type RCCBs, high-permeability cores are employed, with permeability reaching up to 500,000 at 50 Hz to ensure precise current detection. For Type A RCCBs, which require detection of pulsating DC residual currents, low remanence (low Br) cores are used. These offer permeability up to 180,000 at 50 Hz, with a dynamic-to-static permeability ratio (U_dyn/U_sin) of ≥ 0.85, ensuring reliable operation under varying conditions.

Energy Meter

Current sensors use the nano core with a rectangular hysteresis loop, due to the high Br, the nano core provides a good linearity and accuracy, reaching class 0.05-0.5 and can be used in a wide temperature range from -55℃ to 130℃.

Innovation. High quality. Performance.

Continuing to provide the highest quality products to our partners has always been Aona’s core commitment.