Expertise & Innovation

This page summarizes nanocrystalline material performance using BH curve data, frequency behavior and manufacturing robustness. It also highlights stability and repeatability results for nanocrystalline ribbons and cores across EV, industrial and renewable energy power electronics.

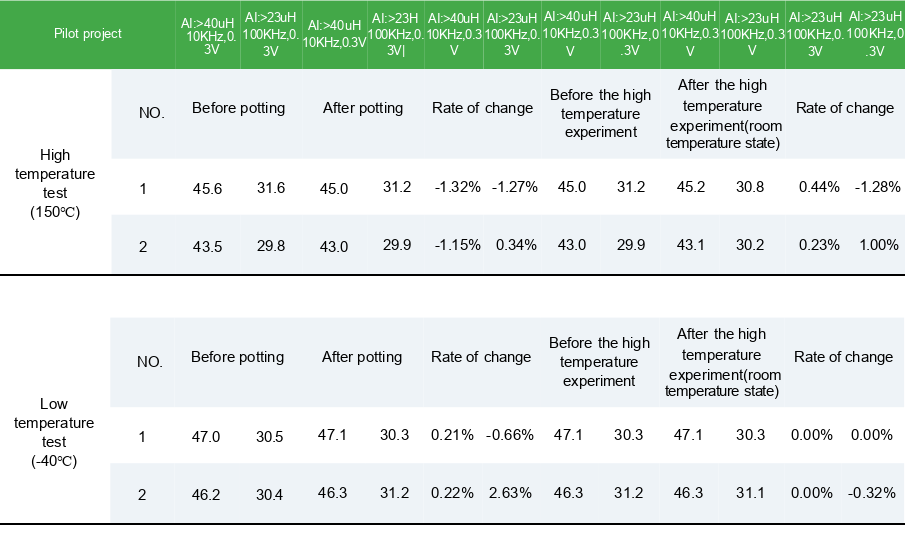

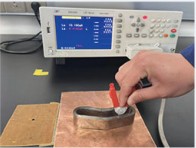

Thermo-mechanical stability

After potting, the nanocrystalline core assembly shows excellent stability during –40°C to +150°C temperature cycling, with inductance variation controlled within ±5%.

Product name

Magnetic Core

Size

87*26*27/71*10*27/3.5

Performance requirements

- AL:≥40uH @10kHz,0.3V

- AL:≥23uH @100kHz,0.3V

Material comparison: 719 vs 782

719 Stress test of product under arbitrary shape

- 10kHz 0.3VL=10.1μH

- 100kHz 0.3VL=8.4μH

- 10kHz 0.3VL=10.3μH

- 100kHz 0.3VL=8.6μH

- 10kHz 0.3VL=10.2μH

- 100kHz 0.3VL=8.5μH

remark

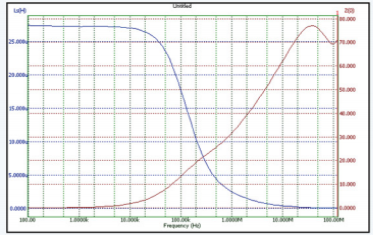

- 100 kHz highest impedance (Z) material

- Best stress stability (The average inductance remains unchanged when the deformation remains 80%)

- Application areas: cut cores, coated cores (spray), large custom-shaped cores, automotive.

782 Stress test of product under arbitrary shape

- 10kHz 0.3VL=42.39μH

- 100kHz 0.3VL=19.03μH

- 10kHz 0.3VL=41.45μH

- 100kHz 0.3VL=16.29μH

remark

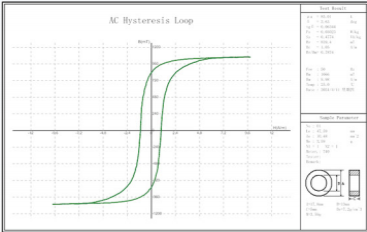

- 100 kHz highest permeability material

- Stress stability (70% average inductance at 80% deformation)

- Application areas: Circular cores.

Magnetic curves & material properties

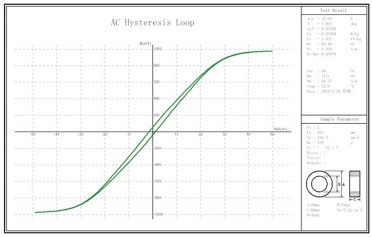

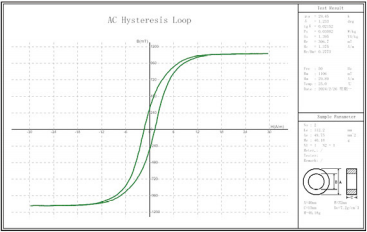

719 BH curve

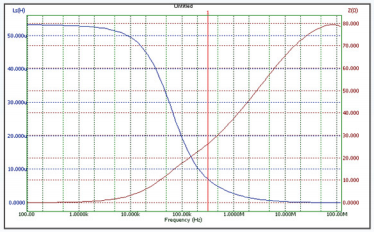

719 Full frequency curve

740 BH curve

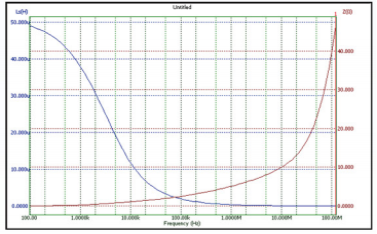

782 Full frequency curve

782 BH curve

740 Full frequency curve

Iron-based ultrafine crystal ribbon

Product Introduction

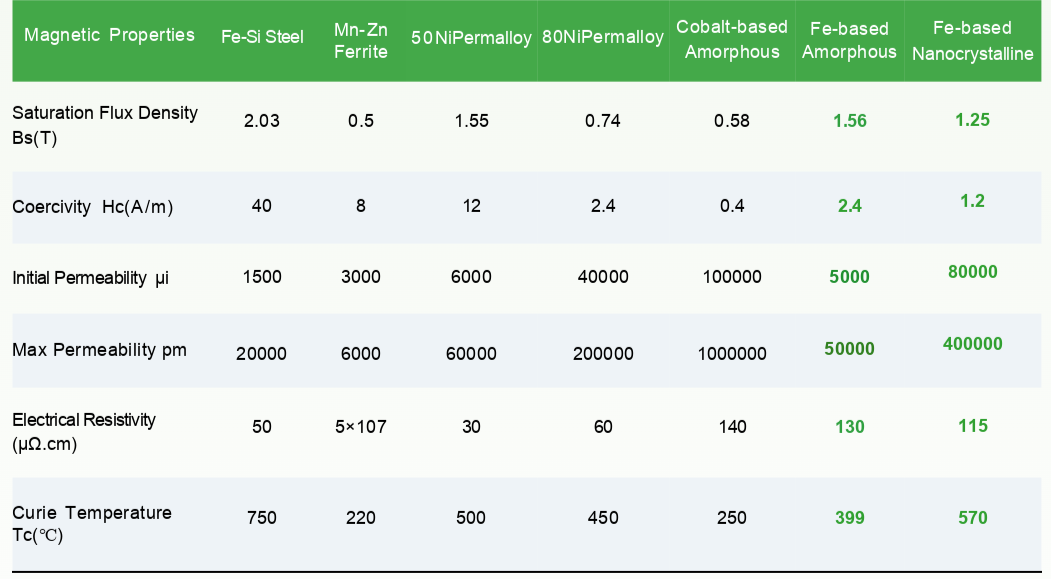

Iron – based nanocrystals are composed of Fe, Nb, Cu, Si, B, etc. When iron – based amorphous alloys containing Cu and Nb are annealed above the crystallization temperature, they will form a very fine grain structure with a grain size of only 10 – 20 nm. The crystalline material formed by this amorphous alloy after special crystallization and annealing is called a nanocrystalline alloy. The nanocrystalline material has excellent characteristics such as high saturation magnetic induction strength, high permeability, low coercivity, low loss and good stability, high strength toughness, wear resistance and corrosion resistance. As a nanocrystalline alloy material with the best performance and price ratio in metal soft magnetic materials, it can replace silicon steel, permalloy and Ferrite has become an ideal material for medium and high frequency transformers, transformers, and inductive components.

Application Areas

It can replace silicon steel, permalloy and ferrite as the main transformer, control transformer, filter inductor, energy storage inductor, reactor, magnetic amplifier, saturation reactor core, EMC filter common – mode inductor and differential – mode inductor core, and ISDN micro – isolation transformer core in various forms of high – frequency (20kHz – 100kHz) switching power supply. At the same time, it is widely used in various types of transformer cores with different precision.

Performance Characteristics

High saturation magnetic induction intensity, high permeability, low coercivity, low loss and good stability, wear resistance, corrosion resistance, while having a low price, it has the best performance price ratio among all metal soft magnetic materials.

Physical Properties

Saturated magnetic induction intensity Bs

1.25T

Curie temperature

570℃

Crystallization temperature

510℃

Saturation magnetostrictive coefficient

27×10⁻⁶

Hardness

880kg/mm²

Density

7.18g/cm³

Resistivity

130μΩ-cm

Performance Comparison Table

Innovation. High quality. Performance.

Continuing to provide the highest quality products to our partners has always been Aona’s core commitment.